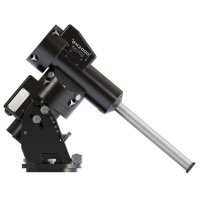

10Micron GM2000HPS II Combi Portable Equatorial Mount

Price as Configured: $17,847.00

Please note that, unless you are ordering a complete package, you must choose a saddle to go with the mount. The mount, by itself, does not include a saddle.

Tell us what you're looking for, and we’ll point you in the right direction. Email Us.

Why the 10Micron GM2000HPS Mounts Don’t Include "Through-the-Mount" Power or Data Connections Running to the Saddle

Understanding the Design Constraints

It’s not a question of design philosophy so much as engineering constraints. Two key factors explain why 10Micron mounts—including the GM1000HPS, GM2000HPS II Combi do not feature built-in power, USB, or Ethernet internal pass-throughs.

1. On-Axis Encoder Configuration and Cable Routing Limitations

Each 10Micron mount uses high-precision on-axis absolute encoders. These encoders are integrated directly on the right ascension and declination axes for exceptional pointing and tracking accuracy.

However, this design leaves very little physical space inside the mount body to route thick, shielded power or data cables.

Adding internal wiring near the encoder assemblies and communication lines could introduce:

-

Electrical interference that affects encoder signal integrity

-

Mechanical stress or wear points within the precision-balanced axis system

-

Increased maintenance complexity for field or observatory service

This is where 10Micron’s conservative engineering approach comes in. The company will not include a feature unless it can be implemented with the same level of reliability that defines their tracking and pointing performance.

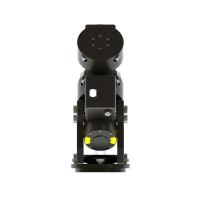

2. The GM2000HPS “Combi” Design and Connector Constraints

When 10Micron replaced the single-piece Monolithic GM2000HPS with the two-piece Ultraport (Combi) model, the goal was to make one mount suitable for both portable and permanent installations, while promoting streamlining production.

In this design, the upper and lower halves of the mount connect through a large, multi-pin interface that already carries power (motor and encoder), control, and encoder signals.

Expanding that interface to add another 6–10 conductors for through-mount power or data would:

-

Require a physically larger, heavier connector

-

Introduce potential interference between high-current power and low-noise encoder lines

-

Complicate field disassembly and increase manufacturing costs

From both an electrical and mechanical standpoint, the trade-offs outweigh the benefit.

3. The Practical and Philosophical Bottom Line

The decision reflects a combination of practical engineering limitations and 10Micron’s conservative design philosophy.

As a European precision manufacturer, the company prioritizes proven reliability and mechanical simplicity.

In short:

If it isn’t broken, don’t fix it.

If it risks the stability of sub-arcsecond tracking performance, it doesn’t go in the mount.

4. How Users Typically Manage Cable Routing

Many 10Micron owners use external cable management solutions—such as flexible cable wraps, quick-disconnect harnesses, or custom dovetail brackets in conjuction with scope-top power and communications distribution—to keep systems tidy and reliable.

In fixed observatory installations of the larger GM3000HPS and GM4000HPS, cables are routed through pier conduits that isolate power and data lines from external power and data lines.